Building Strength, Engineering Excellence.

About Us

Engineering Trust, Building the Future.

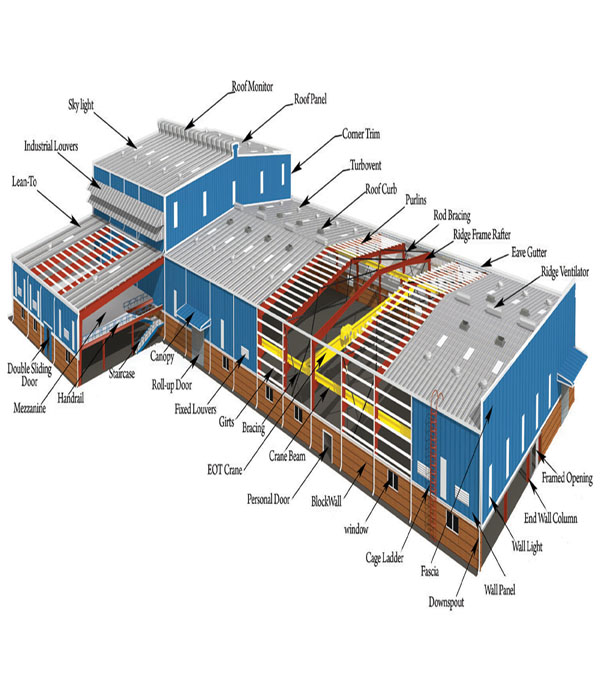

We are a leading name in the industry, dedicated to providing tailored solutions that meet the unique needs of each customer. In pre-engineered buildings, structural components serve as the primary load-bearing and support systems. Their shape and size are determined by the specific application and project requirements. All our structural steel sections and welded plate members are meticulously designed in accordance with the latest standards set by the American Institute of Steel Construction (AISC) and the Metal Building Manufacturers Association (MBMA), ensuring compliance with design criteria, fabrication guidelines, and installation practices for superior performance and safety.

- Strength You Can Trust, Quality You Can Rely On!

- Building Excellence with Every Product!

Services

Engineered for Strength, Designed for Excellence!

Quality | Integrity | Innovation | Customer Focus | Growth

Built on Strength, Driven by Innovation.

We uphold integrity, quality, and innovation in everything we do, ensuring transparency, excellence, and forward-thinking solutions.

Construction is the process of building

%

Trusted Quality

Frequently Asked Questions

Yes, PEB extensions are possible. Onsite measurements, along with existing column and foundation details, are required for accurate design calculations.

To offer the most accurate and competitive quote, we need details such as the proposed shed’s length, width, eave height, brick wall height, number of openings, and the project site location.

Yes, sheds with sheet cladding tend to be 2 to 3 degrees Celsius warmer compared to those with fully brick walls. However, the temperature can be regulated by installing Turbo Ventilators or Ridge Ventilators.

Primary structures will arrive with two coats of primer. Enamel paint will be applied on-site, with supply by the customer and application by the erection contractor.